Raman Spectroscopy: A Versatile Tool for Food Safety, Pharmaceuticals, and Beyond

Introduction:

As global supply chains become more complex, Raman spectroscopy has emerged as a vital tool for ensuring product quality and safety. It is particularly effective in detecting food adulteration, a serious issue in dairy, alcohol, and processed foods. Beyond this, its ability to provide fast, non-destructive analysis makes it invaluable for verifying authenticity, ensuring compliance, and enhancing quality control in industries such as pharmaceuticals and environmental monitoring. With its precision and versatility, Raman spectroscopy is helping build greater trust in modern supply chains.

Raman’s Legacy: The History of Raman Spectroscopy

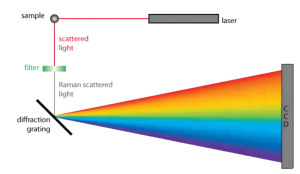

Raman spectroscopy traces its origins to 1928, when Indian physicist C.V. Raman discovered the light-scattering phenomenon that bears his name and the work that earned him the Nobel Prize in 1930. For decades, Raman technology remained confined to specialized laboratories due to complex instrumentation and sensitivity challenges. The 1980s brought critical advancements with lasers and detectors, enabling practical applications. Today, miniaturized spectrometers and surface-enhanced techniques (SERS) have transformed Raman into a portable, high-sensitivity tool used everywhere from food safety inspections to pharmaceutical quality control and even pollutant monitoring. This journey from Nobel Prize-winning discovery to field-deployable technology demonstrates its enduring scientific value.

Why Raman Technology Stands Out

- Speed and Efficiency: Results are delivered in seconds, enabling real-time decision-making on factory floors, in markets, or during inspections.

- Non-Destructive Testing: Samples remain intact, allowing for further analysis or legal verification if needed.

- Versatility: Raman devices can detect a wide variety of adulterants, from starch in paneer to industrial chemicals in beverages, all in a single test.

- User-Friendly: Portable Raman spectrometers are designed for field use and are battery-operated, rugged, and intuitive, making them ideal for inspectors and quality control teams.

SERS: Supercharging Raman Technology

1. Food & Beverage Industry

- Dairy: Identifies melamine, vegetable oils, or detergents in milk products.

- Alcohol: Uncovers dilution, toxic additives (e.g., methanol), or counterfeit labeling.

- Oils & Spices: Detects synthetic dyes or filler agents like Sudan Red in chili powder.

2. Pharmaceuticals & Healthcare

- Drug Authentication: Rapidly distinguishes between genuine and counterfeit tablets.

- Quality Control: Ensures active pharmaceutical ingredient (API) consistency in production.

- Biomedical Diagnostics: SERS aids in early cancer detection through biomarker analysis.

3. Environmental & Industrial Uses

- Pollutant Monitoring: Identifies microplastics, heavy metals, or pesticide residues in water/soil.

- Material Analysis: Verifies polymer composition or detects defects in manufacturing.

How It Works in Practice:

A typical inspection with a portable Raman device is straightforward:

- A small sample is scanned with a handheld device.

- The spectrometer instantly compares the sample’s fingerprint to a built-in library of authentic and adulterated substances.

- Results are displayed clearly, often using a simple traffic-light system (green for authentic, yellow for suspect, red for adulteration).

- Advanced software can even quantify the level of adulteration, supporting regulatory enforcement and quality control.

Real-World Impact:

With Raman and SERS, food safety teams can:

- Conduct 100+ tests per day per inspector, vastly outpacing traditional lab-based methods.

- Instantly differentiate between pure and adulterated products, even when adulterants are present in minute amounts.

- Preserve samples for further verification, supporting transparent and defensible quality control processes.

Advantages Over Traditional Methods:

| Feature | Traditional Tests | Raman Analysis with NutaNXT |

| Time to Result | Hours to days | Seconds |

| Sample Preservation | Often destroyed | Remains intact |

| Range of Adulterants | Limited (often one) | Multiple in one test |

| Field Usability | Lab-bound | Portable, on-site |

| Objectivity | Visual/manual | Digital, unbiased |

Raman Spectroscopy Analysis with NutaNXT:

Rapid Drug Identification

Problem: Customs and law enforcement need to quickly identify suspicious powders, pills, or liquids that are often concealed in luggage or mail without destroying evidence. Traditional chemical tests (like colorimetric kits) are slow, destructive, and prone to false positives.

Raman Solution:

Handheld Raman Rx scanners can:

- Analyze substances through sealed containers (plastic bags, glass vials) in <10 seconds.

- Distinguish between fentanyl, cocaine, methamphetamines, and cutting agents (like baking soda) with >90% accuracy.

- Create court-admissible reports by preserving the sample intact for lab verification.

Conclusion:

Raman spectroscopy is redefining product quality and safety by making adulteration detection faster, easier, and more reliable than ever before. For regulators, manufacturers, and anyone committed to industrial integrity, adopting this technology is a proactive step toward safer products and stronger consumer confidence. Now is the time to invest in smarter, science-backed solutions that protect both public health and industry reputation.

Investing in Raman technology goes beyond solving today’s challenges. It secures long term trust and reliability across supply chains for the future.